Advertisement

The sprawling new Siemens facility in Fort Worth isn't just another American factory. It's part of a larger shift, where artificial intelligence and automation are no longer just buzzwords but are integral to the foundation. Siemens has poured $190 million into this 430,000-square-foot site, and it's not just about machines; it's about building smarter ones. This new hub is designed to speed up the production of electrical equipment used in data centers, EVs, industrial facilities, and power grids. But at its heart, it's a proving ground for what AI-driven manufacturing can look like when it's built from the ground up.

There’s a lot of talk about reshoring and rebuilding U.S. industrial capacity, but most headlines focus on the politics. This Fort Worth facility tells a quieter story: one that’s technical, long-term, and focused on outcomes. Siemens didn’t just invest in concrete and steel; it invested in processes, data infrastructure, and embedded AI systems. And it’s not only about what comes off the line, but how it’s made.

At a glance, you might not spot what makes the Siemens Fort Worth manufacturing hub different from a standard facility. However, beneath the surface, AI is woven into nearly every part of the production pipeline. From digital twins that simulate the behavior of machines before they're built to predictive maintenance tools that forecast breakdowns, the emphasis is on autonomy. Not in the sci-fi sense—no robots taking over the world—but in removing slow, manual decisions from the chain.

Instead of relying on time-based schedules, AI monitors every part of the assembly process. For example, if one segment starts to lag due to mechanical friction or a slight misalignment, the system can flag it and either self-correct or prompt intervention. It cuts downtime, raises output, and allows for shorter lead times, which is critical as industries like EVs and data centers demand faster responses.

The term 'AI' in industrial automation is often thrown around, but Siemens's approach is less about headline-grabbing experiments and more about embedded intelligence. Software systems track how each product component moves through the process, learning from patterns and adjusting schedules in real-time. That reduces waste and boosts throughput—not by working faster, but by working smarter.

This kind of learning architecture is crucial when creating complex electrical equipment, much of which has tight tolerances and stringent safety standards. AI helps enforce quality without the cost of excessive human inspection, while still letting engineers step in when things don't look right. It's not a full handoff to machines—it's a partnership.

There's a reason Siemens picked Fort Worth, and it wasn't just land prices or tax breaks. Texas sits at the crossroads of U.S. industry, located near power hubs, logistics corridors, and major customers in the energy, technology, and transportation sectors. That proximity means faster delivery times and easier integration with customers' systems.

Furthermore, Siemens expects Fort Worth to become a hub for talent. The company has already begun hiring and training workers in automation technology, AI-assisted design, and high-precision manufacturing. This is part of a broader effort to help the American workforce adapt to machine-led workflows—not as a replacement, but as a complement. With skilled labor shortages across the U.S., building a plant like this serves as much as a training initiative as it does a production facility.

Texas also gives Siemens flexibility to adapt the plant's layout and technology over time. The modular design allows for equipment and AI systems to be swapped or upgraded as products evolve. In that way, this isn't a static factory. It's more like a platform, designed to evolve without shutting down.

What Siemens is doing in Fort Worth could have a ripple effect far beyond its products. It sends a signal to other manufacturers: AI isn't just for data centers or cloud software. It's ready for the floor, the parts bin, and the inspection rig. And it's not some giant leap forward—it's the small, quiet steps that happen thousands of times a day inside a place like this.

In many ways, this hub is a response to the failures of globalized supply chains during the last few years. Companies that relied solely on just-in-time models and overseas factories were caught off guard when disruptions occurred. Siemens' move shows that with AI in industrial automation, it's now more realistic to bring that work home, without taking a hit on cost or efficiency.

It's also a rejection of the old divide between tech and industry. The factory floor is no longer separate from the cloud. The same kind of analytics used to optimize ad campaigns or cloud resources is now being used to tweak torque levels or balance production loads. As AI continues to improve, those connections will become tighter.

If it works as Siemens plans, Fort Worth will stand as a blueprint for how to do things differently. Not by abandoning manufacturing's past, but by threading software and learning into the bones of the building.

Siemens’ Fort Worth hub shows how steady, thoughtful change can reshape manufacturing. This $190 million factory blends AI and machinery seamlessly, focusing on precision and reliability rather than spectacle. Every circuit, panel, and component is monitored by machines that watch each other, freeing people to solve real problems. The AI isn’t a bolt-on feature—it’s built into the framework, making the entire operation smarter and more consistent. If this model scales, it could influence the future of American manufacturing, showing how data and AI can improve output without unnecessary complexity. Quietly efficient and repeatable, the Fort Worth hub serves as a working example of how technology can support industry without overshadowing it.

Advertisement

Know how AI transforms Cybersecurity with fast threat detection, reduced errors, and the risks of high costs and overdependence

Learn the top 5 AI change management strategies and practical checklists to guide your enterprise transformation in 2025.

IBM showcased its agentic AI at RSAC 2025, introducing a new approach to autonomous security operations. Learn how this technology enables faster response and smarter defense

Watsonx AI bots help IBM Consulting deliver faster, scalable, and ethical generative AI solutions across global client projects

How IonQ advances AI capabilities with quantum-enhanced applications, combining stable trapped-ion technology and machine learning to solve complex real-world problems efficiently

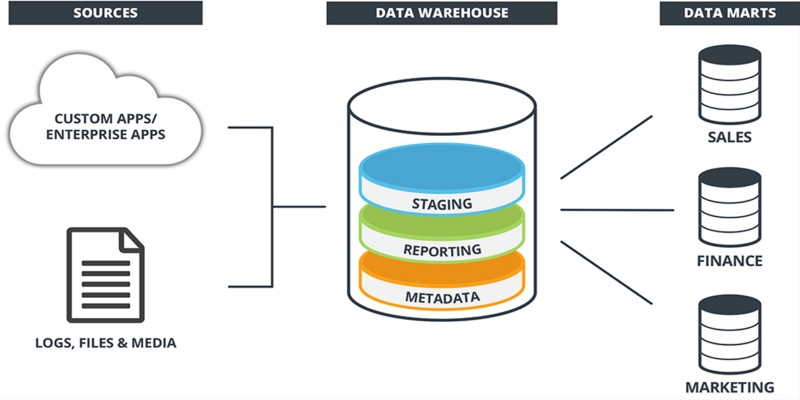

Learn what a data warehouse is, its key components like ETL and schema designs, and how it helps businesses organize large volumes of data for fast, reliable analysis and decision-making

Discover the latest machine learning salary trends shaping 2025. Explore how experience, location, and industry impact earnings, and learn why AI careers continue to offer strong growth and global opportunities for skilled professionals

How IBM expands AI features for the 2025 Masters Tournament, delivering smarter highlights, personalized fan interaction, and improved accessibility for a more engaging experience

At CES 2025, Hyundai and Nvidia unveiled their AI Future Mobility Program, aiming to transform transportation with smarter, safer, and more adaptive vehicle technologies powered by advanced AI computing

How the Model-Connection Platform (MCP) helps organizations connect LLMs to internal data efficiently and securely. Learn how MCP improves access, accuracy, and productivity without changing your existing systems

Sam Altman returns as OpenAI CEO amid calls for ethical reforms, stronger governance, restored trust in leadership, and more

Google risks losing Samsung to Bing if it fails to enhance AI-powered mobile search and deliver smarter, better, faster results